CNC Milling & Turning Services

At Chardon Metal Products Co., we have been providing precision machining and fabrication since our inception in 1945. Throughout our history, we have continued to broaden our manufacturing services, including the introduction of CNC turning and milling in the 1980s. Since then, we have acquired a full range of advanced CNC equipment, allowing us to offer state-of-the-art machining at extremely close tolerances and high volumes. Working with a broad range of materials, our CNC processes can accommodate workpieces in many different dimensions, and have been relied on by a full breadth of industries. Furthermore, with our ISO 9001:2008 certification, we guarantee the best quality machining at every step of the process.

Using our advanced CNC capabilities, we build to our customers’ exact specifications, offering design assistance and prototyping. Our equipment includes lathes, mills, and multi-axis machining centers, featuring four-axis milling capabilities and up to 11 Axis turning capabilities. Employing this machinery, we are able to offer multiple machining processes, including milling, drilling, boring, and burnishing, as well as contour, form, taper, straight, and hard turning. External and internal threading is also available, along with tapping, knurling, broaching, counterboring, countersinking, pocketing, profiling, and a whole host of others. In-house fixturing and tooling is available.

Our selection of premium quality equipment can accommodate workpieces in a broad variety of dimensions. This includes part diameters from 0.375″ to 13″, part lengths from 0.125″ to 14″, part widths from 0.125″ to 31″, part heights from 0.125″ to 23″, and weights up to 500 lbs. With our multi-axis live tooling, precision machining can be performed in one holding, increasing positional tolerances and quality while increasing process efficiency. We take pride in our accuracy, with tolerances of ±0.0002″ for concentricity, ±0.00025″ for outer diameter, ±0.0005″ for inner diameter, and ±0.002″ for lengths over 6″ regularly achieved.

We work with a wide range of materials, including many different metals and plastics. These include carbon and alloy steels, brass, aluminum, bronze, stainless steel, nickel, iron, titanium, hardened alloys and hardened stainless steel. Our work with plastic polymers includes ABS, acetal, nylon, acrylic, phenolic, polyethylene, polystyrene, PVC, PVDF, and PTFE, among others. We are a full service shop, supplementing our CNC machining capabilities with a number of additional services. Some of these include assembly, welding, plating, painting passivating, heat treating, and anodizing are all available, as well as supply chain assistance, with just-in-time (JIT), Kanban, and stocking programs available.

We work in volumes ranging from 10 to 50,000, with emergency and rush services available. To learn more about our CNC turning and milling, please see the details below or contact us directly.

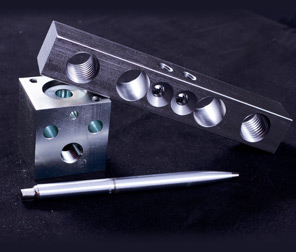

Photo Gallery

CNC Milling & Turning Highlights

- General Capabilities:

-

Build to Customer Specifications

Design Assistance

Just-In-Time (JIT)KANBAN

Stocking Programs

Prototyping

- Machining Processes:

-

Boring

Broaching

Burnishing

Counterboring

Countersinking

Drilling

Facing

Internal Forming

Knurling

Milling

Parting/Cutting

Pocketing

Profiling

ReamingRoll Tapping

Thread Milling

Thread Whirling

Turning:- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

- Hard Turning

Threading

- External

- Internal

Tapping

- Equipment Capabilities:

-

Bar Feed

CAD Design Services

CAM Programming ServicesCNC Control Capabilities

Milling

Reverse Engineering

- Machinery Axis:

-

2,7,9, and 11-Axis Lathes

4 – Axis Mills

Live Tooling

- Fixturing:

-

Four-jaw chuck

In-House Fixturing & ToolingPallets

Three-jaw Chuck

- Minimum Part Diameter:

-

0.375 in

- Maximum Part Diameter:

-

13 in

- Minimum Part Length:

-

0.125 in

- Maximum Part Length:

-

14 in

- Minimum Part Width:

-

0.125 in

- Maximum Part Width:

-

31 in

- Minimum Part Height:

-

0.125 in

- Maximum Part Height:

-

23 in

- Maximum Part Weight/Maximum Lifting Capacity:

-

500 lb

- Concentricity Tolerance (±):

-

0.0002

- Outer Diameter Tolerance (±):

-

0.00025 in

- Inner Diameter Tolerance (±):

-

0.0005 in

- Length (Over 6 Inch (in)) Tolerance (±):

-

0.002 in

- Materials (Metals):

-

Alloy Steels

Aluminum

Brass

Bronze Alloys

Carbon SteelCopper

Iron

Nickel

Stainless Steel

Titanium

- Materials (Plastic Polymers):

-

Acetal

Acrylic

Acrylonitrile Butadiene Styrene (ABS)

Fiberglass Reinforced Plastics

Nylon

Phenolic

Poly Tetra Fluoro Ethylene (PTFE)

Polyamide-Imide

PolycarbonatePolyetheretherketone (PEEK)

Polyetherimide

Polyethylene

Polyphenylene Sulfide

Polypropylene

Polystyrene

Polysulphone

Polyvinyl Chloride (PVC)

Polyvinylidene Fluoride (PVDF)

- Secondary Services Offered:

-

Anodizing

Assembly

Bending

Centerless Grinding

Counter Sinking

Drilling

Etch and ChromatingHeat Treating

Passivating

Plating

Pressing

Reaming

Tapping

Welding

- Production Volume:

-

10 minimum

50,000 maximum

Specialty Production Shop

Prototype

Low VolumeSmall Run

High Volume

Large Run

Long Run

Large Scale Production Volume Run

- Lead Times Available:

-

Emergency services available

Quoted on job by job basis

Rush Services Available

Additional Information

- Industry Focus:

-

Aerospace

After Market Automotive

Class 8 Truck- Steering

- Braking

Construction

Consumer Goods

Diesel Engines

Electrical

Electronics

Energy

Food ProcessingHand Tools

Marine Components

Medical Hardware

Military

Mining

Natural Gas

Off Highway

Oil and Gas

Petroleum

Railroad

Refrigeration

- Industry Standards:

-

American Society for Testing and Materials (ASTM)

Military Specifications (Mil-Spec)

National Aerospace And Defense Contractors Accreditation Program (NADCAP)

Restriction of Hazardous Substances (RoHS) (Compliant)

Society of Automotive Engineers (SAE)American National Standards Institute (ANSI)

American Society of Mechanical Engineers (ASME)

American Welding Society (AWS)

International Organization for Standardization (ISO)

- Efficiency:

-

Lean Manufacturing